There are different methods that you can choose when deciding in what order to measure the parts of the study.

Run parts in random order

This is the most statistically accurate method of conducting a Gage R&R study. If you have 10 parts, 3 operators, and 3 trials in your study, there are 9 sets of parts. In each set, the operator and trial numbers are fixed and all 10 parts are measured in random order. The order of the sets themselves is also random.

Manually Set Order of Parts

If you have a specific order you wish to measure the parts you can type the numbers into the screen presented when you click the Next>> button. The wizard will check your entries to make sure you do not enter any illegal Part, Trial, Operator combinations or reuse any legal ones.

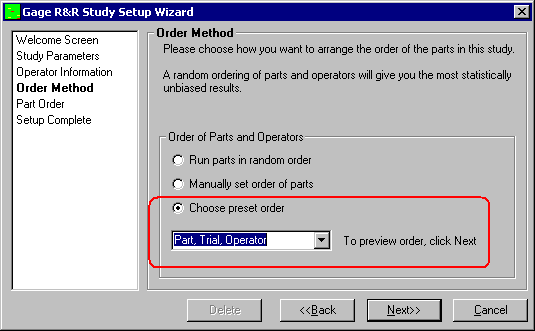

Choose Preset Order

The wizard can fill-in the GR&R test order for you by incrementing the part, trial, and operator.

This time-saving features has 6 combinations of increments listed. They are:

| Increment 3rd | Increment 2nd | Increment 1st |

1 | Part | Trial | Operator |

2 | Part | Operator | Trial |

3 | Trial | Operator | Part |

4 | Trial | Part | Operator |

5 | Operator | Part | Trial |

6 | Operator | Trial | Part |

To understand how the list is generated, the increment sequence mimics the odometer in your car. The least significant word in the list (right side) is incremented first, then the next, and finally the 3rd. The generated sequence can be seen by choosing one of these six preset orders and clicking the Next>> button. If you pick an order you do not want, select the <<Back button and try again. Click the Next>> button to see the next order you chose.

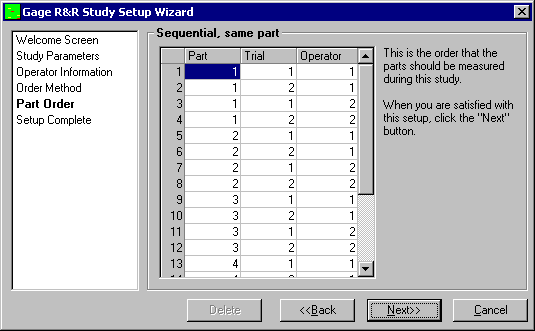

Part Order (automatic)

This screen displays the order the study is conducted. It gives you a chance to see the entire study laid out ahead of time. If you do not like the order you can click the <<Back button and create another random order for all of the parts.

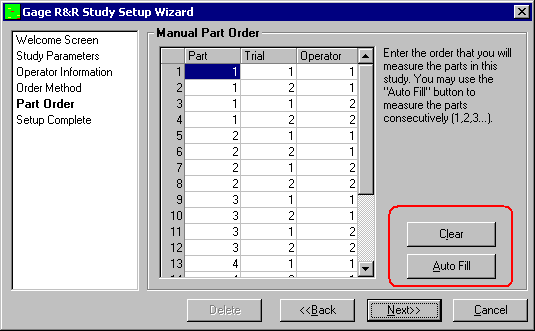

Part Order (manual)

If you choose to specify the order of the parts manually, the Part Order screen is slightly different and the grid is editable. By default the grid is filled in similar to the Sequential with same operator choice but you may fill the grid any way you choose.

Also, there are two buttons that show up only with Manual Part Order. The Clear button clears the grid and fills it with zeros to show which areas have not been entered. The Auto Fill button fills the grid the same as Sequential Same Operator. This screen also checks for a correctly entered list of numbers to ensure the Gage R&R study is valid. This means that each operator must measure each part the appropriate number of times.