Introduction

It is common to have large inspection routines on your CMM with 100 or more features that take 30 minutes or more to run. In cases like this, sometimes a couple of features fail because they are dirty. Since the rest of the features are good, you want to remeasure those few features rather than wait for the entire routine to run again.

Fortunately, if you are using "Always Adapt" in QC-CALC Real-Time, you can do this and only replace the features you measure. Always Adapt uses the feature name to determine where the data should go. Under normal circumstances, if you are using Always Adapt and measure only two of your 100 features, QC-CALC will create a new part with those two features, and the remaining 98 features will be considered deleted.

However, if you are remeasuring a part in QC-CALC, a partial run will only replace the measured features. The remaining features will be left alone.

Directions

- Make sure you are in "Always Adapt" mode. Go to Tools > Options > Data Collection > Actions to do this. In the list at the top of the screen labeled If the number of machine dimensions in part does not match those in the file, choose "Always Adapt."

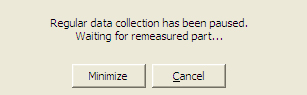

- Right-click the part to remeasure and click Remeasure Record in the popup menu. The following remeasure screen will appear.

NOTE: You do not have to right-click the exact dimension you are remeasuring. Any dimension in the part will do.

Note: You can right-click on any record in the QCC file. It does not have to be the last record.

- Run your partial inspection routine on your CMM. When the measurement results come in, the correct measurements will be replaced, and the remaining measurements will not be touched.

- Continue measuring parts normally.