QC-CALC automatically builds its database when it reads a never before seen “results file” from your CMM. Since QC-CALC has a policy of not asking questions, it must obtain reasonable answers from somewhere. QC-CALC uses a File Creation Default area for these answers that was setup during installation. The file creation default area contains the answers to any questions that would normally have been asked of you. You can change these answers but they may have been incorrect for some situations. Therefore, we provide a tool to change the structure and content of any database previously created. This section gives you an understanding what QC-CALC saves and how to change the settings.

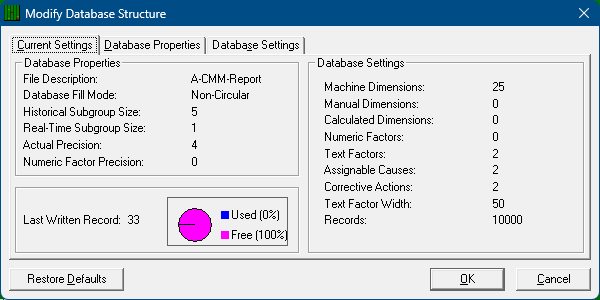

Current Settings

Select menu File – Modify Database Structure and the following window is displayed. This tab summarizes all the information about the currently open database file on one screen. You can change these values from the Database Properties and Database Settings tabs.

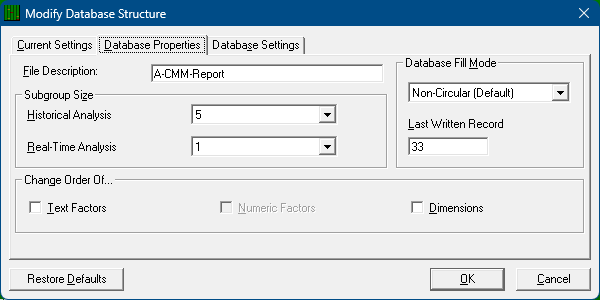

Database Properties

The tab contains the basic organization of the database file. You can modify these values to adjust how QC-CALC displays your data.

File Description

This is a description of the currently open file that may be used to give additional information about the file. If a specific value was not entered the .qcc file name will be save into this area.

Subgroup Size

Historical Analysis

This controls the number of data points that make up a subgroup on the control charts in the statistical menu. The minimum subgroup size is 2 and the maximum is 25.

Real-Time Analysis

This controls the number of data points that make up a subgroup (or points) on the graphs in QC-CALC Real-Time. A subgroup size of 1 is the minimum size where each inspected part is displayed immediately as raw data. If you set the subgroup size to 2, no visible point is displayed until two parts are received. QC-CALC displays the current point within the subgroup in the lower status bar.

Database Fill Mode

This option only applies to Real-Time and tells QC-CALC what to do when the data file becomes full. The maximum parts store in each database is 2,000,000. If the file is circular, QC-CALC automatically wraps around from 2,000,000 back to the first record and begins writing over the old data. If you do not want the old data to be erased, archive the data file to another disk or select non-circular.

Last Written Record

This is the number of the last record that was inspected. The number tells you where new data will be added when data collection or data entry resumes. Changing this number to a lower number will effectively erase the records located beyond that number. For example, if 42 were the last written record, changing this to 40 would cause records 41 and 42 to be overwritten when data is again received from the inspection equipment. If you move it back to 42 before any data is saved, your records are returned.

Change Order Of …

This frame contains three check boxes that allow you to change the column order in which your data is place in the database. For example, you can swap the position of Dimension 1 with Dimension 2 or Text Factor 2 with Text Factor 3, etc. It is rare that you would need this type of maintenance but it is include should you change you part program and need to change the QC-CALC database to match.

Text Factors

These columns are used to record information specific to a part such as operator name, work order numbers, machine names, etc. In this example we swap Text Factor 3 (labeled Plant) with Text Factor 4 (labeled Division).

We start with the screen above and move all five Text Factors to the right panel using the right arrow and then using the vertical upper and down arrow keys, adjust their final position to look like the screen below. Pressing the OK button causes QC-CALC to move all text Factors to the newly selected order.

Numeric Factors

Numeric Factor operate the same but only numbers can be entered in these columns, which are mainly used to record information specific to each part stored in the database as well as to help you filter the data to create a more specific analysis.

Dimensions

The measured values operate the same but only numbers are allowed. These columns contain measurement results for each dimension in the database. A total of 3000 dimensions per part and up to 2,000,000 parts can be stored in one database. You can move or remove any of these columns of numbers to match your latest part program configuration.

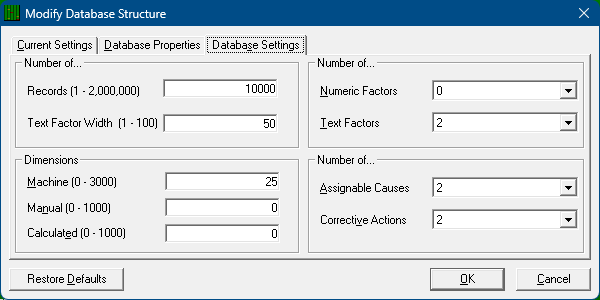

Database Settings

The database settings tab contains items that change the size of the database. You can add or remove records, dimensions, Factors, assignable causes, etc. If you choose a value less than the value shown (existing), you are warned that information will be lost. When you finish and click OK, you see a screen of the selected items to keep and items to discard. You can change the order of each item as well. Each item is briefly discussed.

Number of…

Records (1 – 2,000,000)

This is the number of records (parts) stored in this database. If the number you enter is small than the current amount of records QC-CALC takes the number of records you specify from the newest data and discards the oldest.

Text Factor Width (1 – 50)

This is the width of each label stored in the Text Factor columns of your data file. You may choose any width up to a maximum of 50 characters.

Number of…

Numeric Factors

This refers to the number of columns of Numeric Factors you would like in your database. This number can be larger or smaller than the current value. You will be warned if you enter a value smaller than the present value.

Text Factors

This refers to the number of columns of Text Factors you wish to have converted. You can add, subtract, or move the order of these values.

Dimensions

This is the number of dimensions to convert. QC-CALC has three types of dimensions:

Machine

Dimensions created automatically by receiving data from an inspection machine.

Manual

Extra dimensions not received from an inspection machine and are entered by hand using QC-CALC’s View – Manual Dimensions.

Calculated

You can add Dimensions that are made up of calculations. These are useful for creating features that are not available from the gage. For example, if a plot contains a measure value for one side of a panel and a second value for the other side, you can calculate thickness by subtracting the two dimensions.

Number of…

Assignable Causes

The purpose of an Assignable Cause file is to store your company’s entire standard Causes that occur during the manufacturing process used to trace special events that occurred to a part. This selection lets you decide how many Assignable Causes you want to include. The range is 0 to 3 causes per part.

Corrective Actions

The associated Corrective Actions explains what you did to fix the Cause, however, the number of Assignable Causes do not have to match the amount of Corrective Actions and vice versa. Therefore you may select as many Corrective Actions as you have or desire but limited to 3.