PREREQUISITES

QC-CALC Real-Time 3.4+

INTRODUCTION

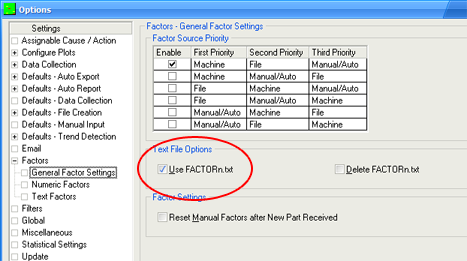

We are frequently asked about how to save information about which machine actually measured the part. The easy answer is Factors/Trace Fields, but it requires you to pass the information with each part. Depending on the inspection equipment (or QC-Gage), this can be a painful process. This article explains how to do it using a facility that has been built into QC-CALC for many years called FactorN.txt. In QC-CALC Real-Time under Tools > Options > Factors > General Factor Settings (Tools > Options > Trace Fields > General Trace Field Settings in 4.0+), there are two checkboxes to Use FactorN.txt and Delete FactorN.txt.

While the original intention was to allow you to drop off text files from a bar code reader which would be read once for the next inspected part and then deleted, this functionality can also be used to leave bread crumbs for data collection about the local PC or inspection equipment. Simply creating a text file called FactorT3.txt in QC-CALC's install directory with the contents "InspectionStation,Milling" will automatically create a text factor/trace field in position 3 of your part file called "InspectionStation" with the value of "Milling".

If you leave the Delete FactorN.txt checkbox unchecked, the file will remain there and be collected for every part in every part file on that workstation. This is the easiest way to keep track of which station is collecting which data in your part files and can even be used to form filters by workstation to compare against other equipment from other stations. For instance, let's assume you have a part file that is shared across multiple workstations with each contributing either the same or different dimensions/characteristics (using Multisource). Adding automatic factors will help to identify where data came from without having to do any extra work during inspection.

STEPS

- In QC-CALC Real-Time, go to Tools > Options > Factors > General Factor Settings (Tools > Options > Trace Fields > General Trace Field Settings in 4.0+).

- Check the checkbox called Use FactorN.txt. Leave the Delete checkbox unchecked since you want the file to remain there.

- Open Notepad and add a label value pair separated by comma. The label will be the name of your factor and the value will be the value of your factor.

Examples:

Machine,3

Station,Turning5

- Save the document into the install directory for QC-CALC ("C:\Prolink\QC-CALC 3.4\" for 3.4 and "C:\Users\Public\Prolink\QC-CALC 4.0\" for 4.0) as FactorNXX.txt where "N" is either N for numeric or T for Text and "XX" is a number between 1 and 30. If you want to save a numeric factor, make sure the value is numeric or it will not work. In other words "Turning5" is not numeric because it has a word in it. "1-5" is also not numeric due to the dash.

Examples:

FactorN5.txt - creates a factor in the 5th numeric position.

FactorT12.txt - creates a factor in the 12th text position.

- Collect data normally. As you do, you should notice the factor(s) being added in addition to any factors/trace fields you're already sending from your inspection equipment or QC-Gage.

**You can create up to 30 numeric and 30 text FactorN.txt files that are collected simultaneously during data collection.

MORE INFORMATION

DISCLAIMER: If you specify FactorT1 and there is already a text factor in position 1 coming from the inspection equipment, you will not see the one from the FactorN file (by default). This is due to the Factor Source Priority. In the image above, you can see that the default enabled option in the grid, is to take Machine over File over Manual.

If you check the 3rd option for File over Machine, then FactorN will win over a factor coming from your equipment. That said, it is usually a better idea not to have a conflict than to try and switch the priority settings. In the end, if there is conflict, one of the values will lose and you won't have all the data you're expecting. Instead, it is recommended that you choose a text or numeric factor/trace field that you are not already using. For instance, if you generally have 3-4 text factors, choose FactorT10.txt as your file name.

CONCLUSION

This is one way to automatically add data from the current workstation from automatic machines. If you are using QC-Gage/Gagestation, you can also use factors that have a default value and are set to invisible. This is a different topic with different caveats, but is also an option.