If the characteristic labels are changed within a part program and sent over to QC-CALC Real-Time, additional characteristics will be created in the part file to hold the "new" characteristics that were received. It is possible to update the characteristic labels automatically, but it takes some setup on the QC-CALC Real-Time side BEFORE the new characteristic labels are sent over.

Here's what you need to do:

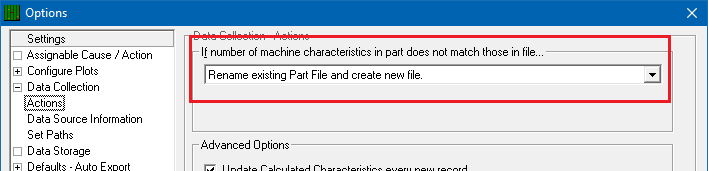

- In QC-CALC Real-Time, use the Tools > Options > Data Collection > Actions area to change the "Always Adapt" setting at the top of the screen to "Rename existing Part File and create new file".

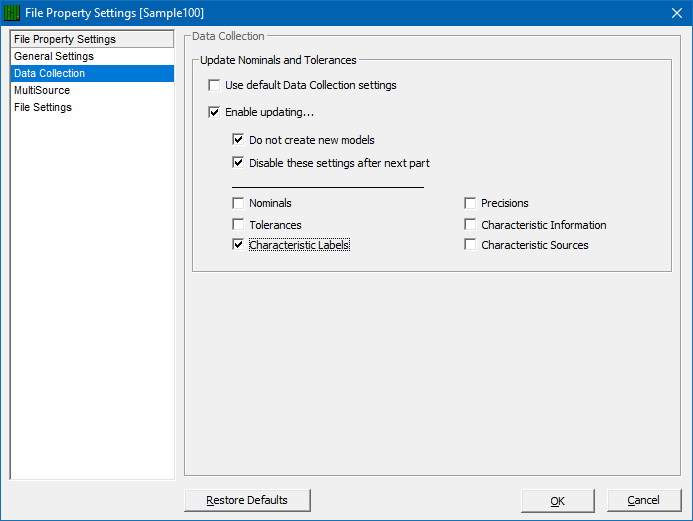

- Open the part file that needs to have the labels updated and go to the File > Properties > General Settings > Data Collection area.

- Uncheck the Use default Data Collection settings option at the top of the screen if it is checked.

- Check the following:

- Enable updating...

- Do not create new models (optional)

- Disable these settings after the next part

- Characteristics Labels

- Click OK on that screen and run your part with the changed labels on the inspection machine.

- When QC-CALC Real-Time collects the new data it should change the labels to match the new values received from the communication file.

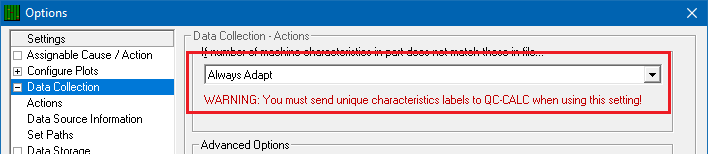

- Now the Tools > Options > Data Collection > Actions area needs to be changed back to the "Always Adapt" setting in order for data collection to work the way it was working before.

NOTE: This process will only work if you do NOT change the total number of characteristics or the characteristic order at the same time you change the labels. If you need to make these other changes also, then do this process first THEN add the new characteristics to your part program or change the order of the characteristics.